> Products > Accesories > Steady rests

> Products > Accesories > Steady rests

GURUTZPE offers a wide range of steady rests to cover any needs that may arise in the varied range of operations performed on its machines.

Easy to adjust, maximum operating rigidity and long life, are the design and construction criteria for our steady rests. For this purpose, we develop hydrodynamic or hydrostatic rolling support solutions, depending on the needs in each application and with various support architectures (closed, C-type…) and drives (manual, hydraulic self-centring…).

Main characteristics:

- Built on a cast body, to guarantee optimum balance between vibration damping and dimensional rigidity (designed by FEM).

- Precise adjustments of studs and drives for a quick set-up on each part.

- Easy operation and maintenance. Action of operator-side studs.

- Various steady rest drive and locking systems on the bed.

- Thousands of steady rests built by GRP guarantee their high reliability.

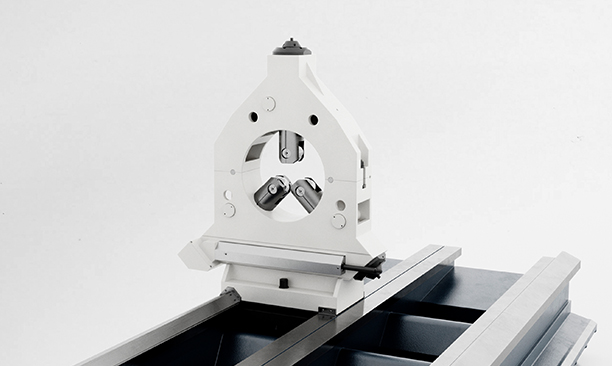

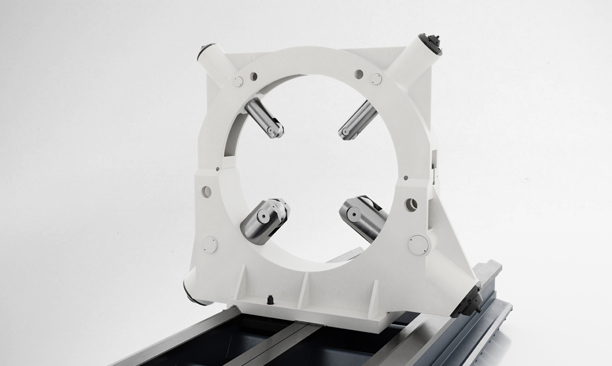

Closed steady rests

Architecture that allows optimal securing of the part, absorbing forces generated in any direction (roughing external turning, internal boring, different milling…):

- With 3 or 4 rollers.

- With possibility of carriage crossing in machines with 4 guides.

- Option to replace the rollers with low friction materials.

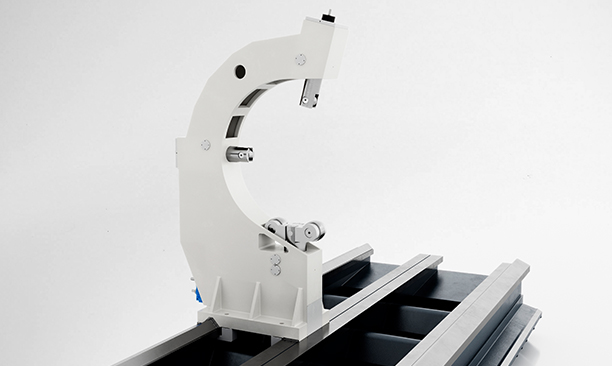

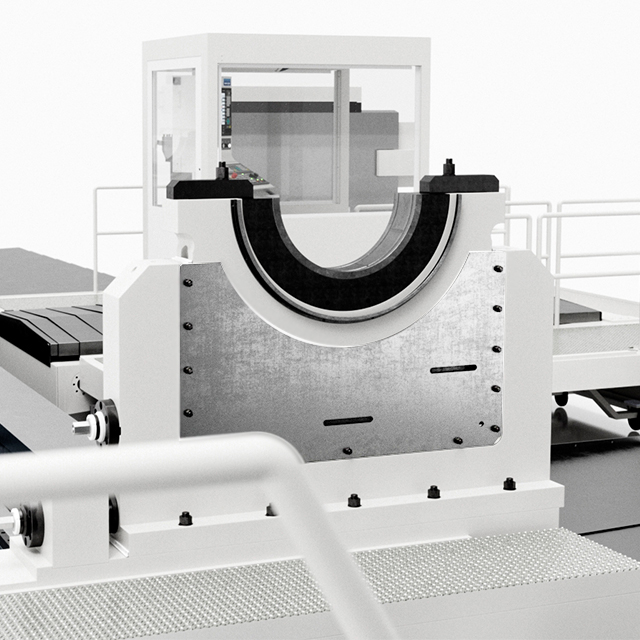

“C” type steady rests

Architecture mainly designed for exterior operations and allowing the least interference between the steady rest and the machining unit, also always allowing crossing with the carriage:

- With single or double tilting lower roller for high loads.

- Possibility of machining to the torque of the steady rest.

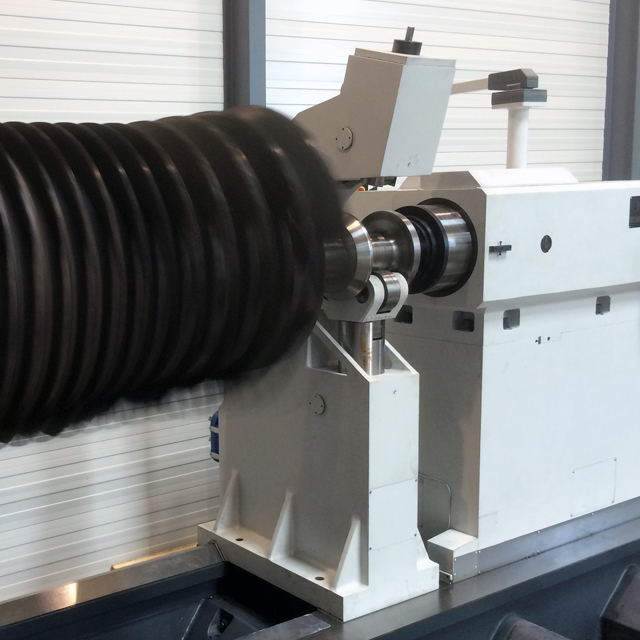

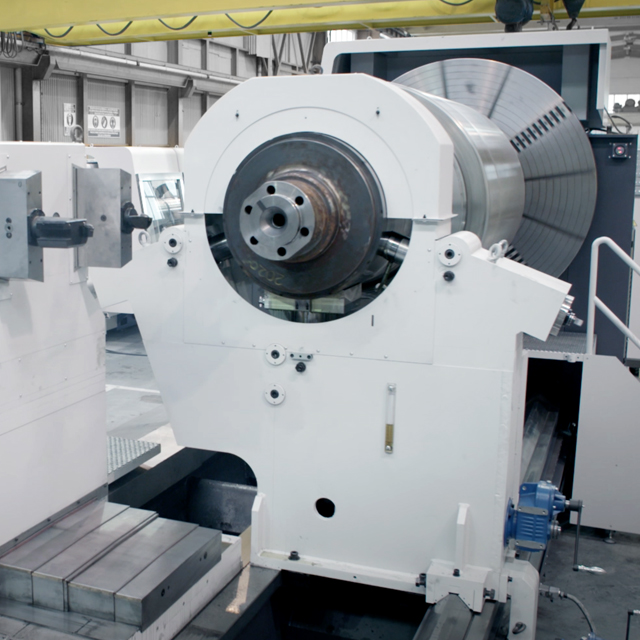

Bed-type steady rest

Architecture that allows the support of larger pieces and weight, as well as the largest range of capacity in diameter.

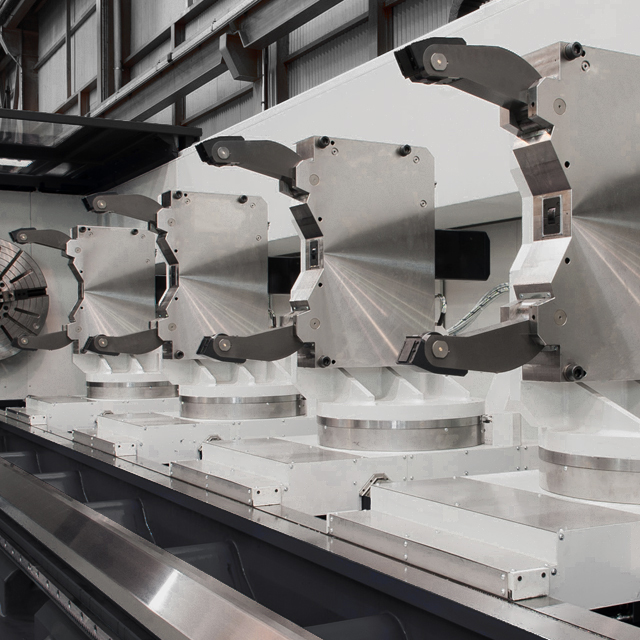

Hydraulic steady rests

Hydraulic steady rests with self-centring rollers, the fastest and most versatile solution for the support and centring of parts. Valid for a wide range of operations both indoors and out, allowing automatic opening and closing during the machining cycle:

- Use of the main manufacturers on the market.

- Wide range of capacities in part diameters and weights.

- Possibility of motorized longitudinal movement and CNC, as well as automatic locking to the bed.

- Possibility of use as a tracking steady rest.

- Possibility of configuring steady rests in tandem in order to improve the rigidity of the support and enable their sequential opening, guaranteeing the securing of the part at all times.

- Integration of 90º rotation modules and linear movements, which facilitate the part loading/unloading and increase the machine’s diameter capacity when not used, without the need for laborious disassemblies.

Hydrostatic steady rests

Designed to give the best solution to the support of the heaviest parts and which have more demanding operations, in turn providing zero marking on its support surface:

- Use of the most advanced hydrostatic systems.

- Half-moon or 3-stud architecture, for a simpler, more economic adjustment to the different diameters.

- Possibility of motorized longitudinal movement and CNC, as well as automatic locking to the bed.

Hydrodinamic steady rests

Designed to give a more economical solution to the support of the heaviest parts and which have more demanding operations, in turn providing the least marking on its support surface:

- Manual or automatic lubrication systems.

- Half-moon or 3-stud architecture, for a simpler, more economic adjustment to the different diameters.

- Possibility of motorized longitudinal movement and CNC, as well as automatic locking to the bed.

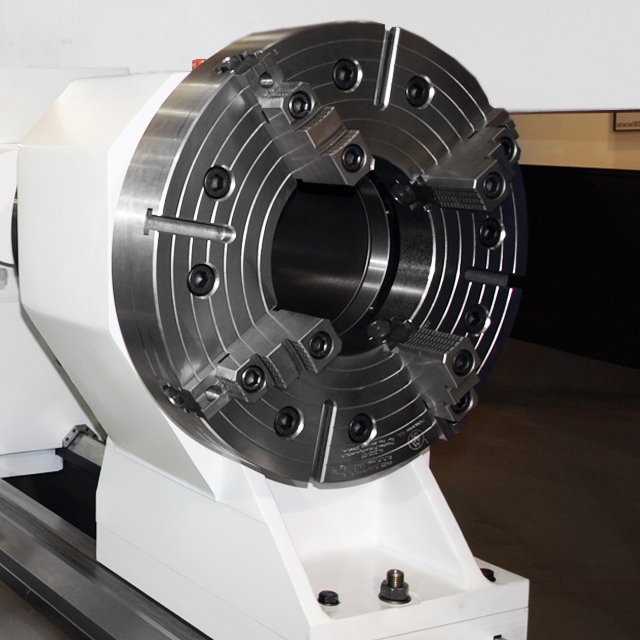

Chuck steady rest

Designed to give the best solution for securing long, slender pieces, even without the need for the piece to be machined in the support/securing area. Ideal for making steady rest records that are concentric with interior holes:

- Standard chuck adaptation to DIN 55026.

- Use of commercial chucks made by the main manufacturers on the market.

- Possibility of 1 or 2 chucks per steady rest.

- Possibility of motorized longitudinal movement and CNC, as well as automatic locking to the bed.

> Products > Accesories > Steady rests