> Products > Accesories > Enclosures

GURUTZPE offers various solutions to respond to protection needs from chips and coolants projected during the various machining processes, taking into account the limitations inherent to the machine’s architecture and its operative-productive conditions by the user.

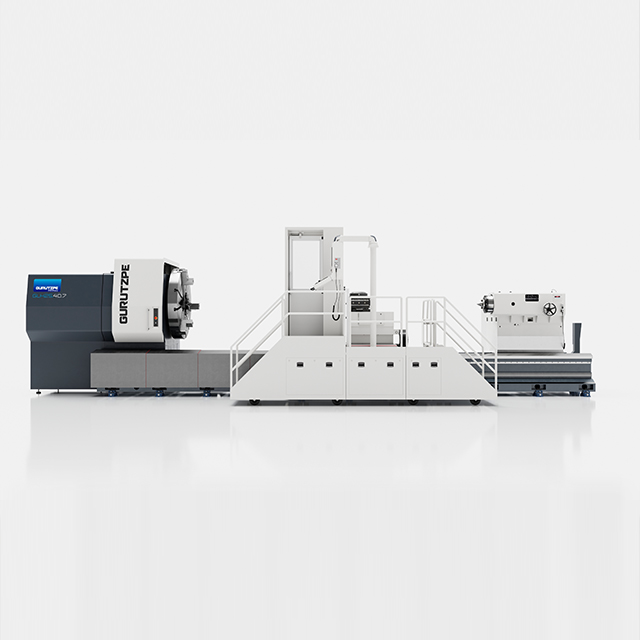

A protective back is common to all machines with tipping up to Ø2000 mm, which serves as a back guard for all projections, as a protective element for all cable holders for steady rests-tailstock centres-carriages and as a base of the guiding system of the corresponding front doors. The geometry and number of these enclosing front doors can be configured to suit the customer’s needs, and can be converted into integral fairing systems. In the architecture of larger machines, partial guards are fitted on the carriage, guaranteeing EC safety requirements at all times.

Main characteristics:

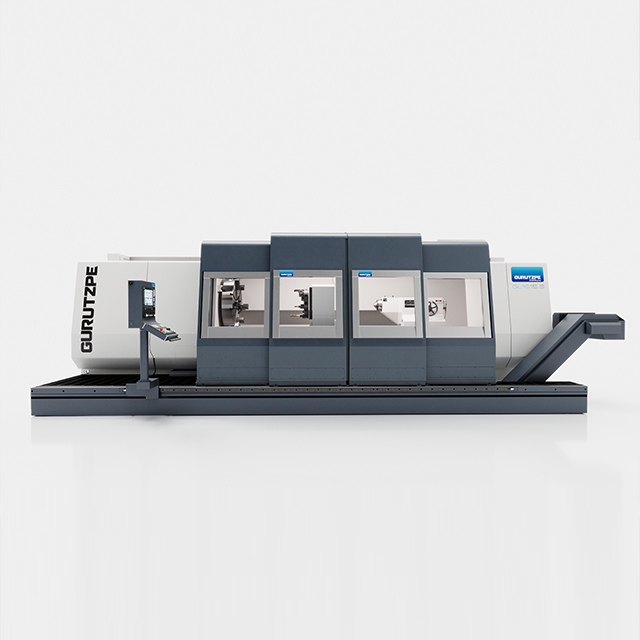

In the same range of machines described above, the enclosure can be made integrally, to create a quasi-hermetic compartment guaranteeing integral collection of chips, cutting fluid and fumes and substantially reducing noise emissions, in addition to improving its level of safety.

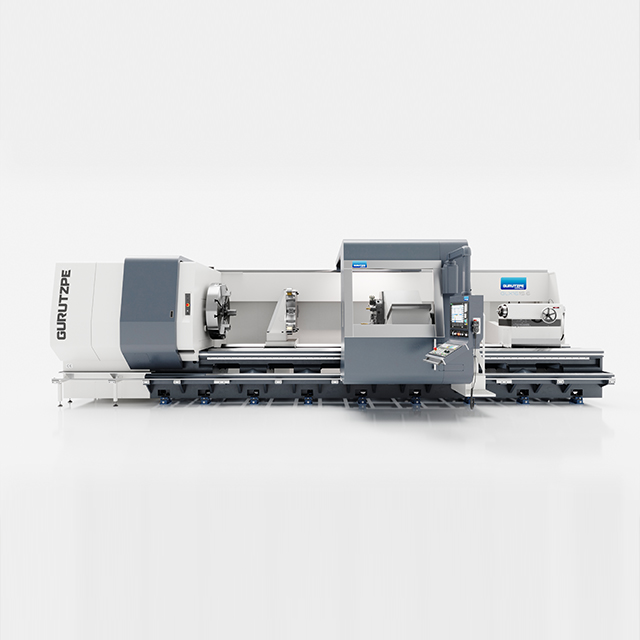

In the GL_10, 13, 16 and 20 range of machines, the rear structure serves as a base and guides for the front enclosing doors, which prevent the projections generated during machining from being released. These front doors can have different configurations and quantities, depending on the customer’s requirements.

For machines that do not have a rear structure (due to their size, length or other reasons…), a partial closing system is designed in the carriage area (according to the EC requirements) in order to prevent chip and cutting fluid projections outside the machine, and allow operators to access the operational machining area.