Description

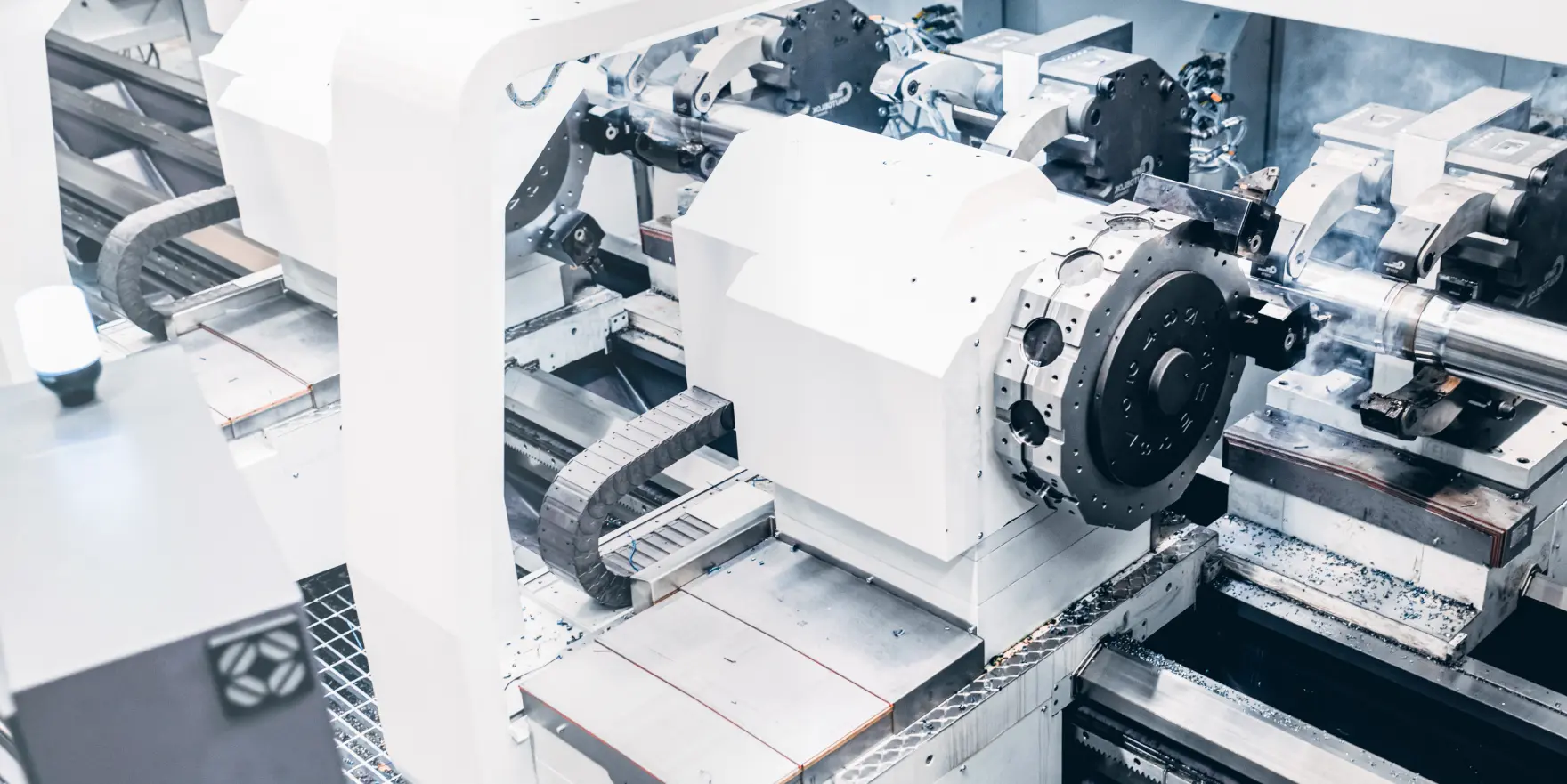

Thanks to its features, the machine is able to offer maximum rigidity, precision and durability.

The whole structure has been manufactured in stabilised cast-iron GG30. The carriages move on special anti-vibration Biplast material, utilizing a small film of oil with centralised lubrication. This combination makes the whole structure perfect for both heavy and highprecision work.

This model is capable of machining an endless number of pieces, from forming rollers, power generation shafts and threaded pipes for the oil industry.

- Øob ≤ 2.000 mm

- Wbc ≤ 25 t