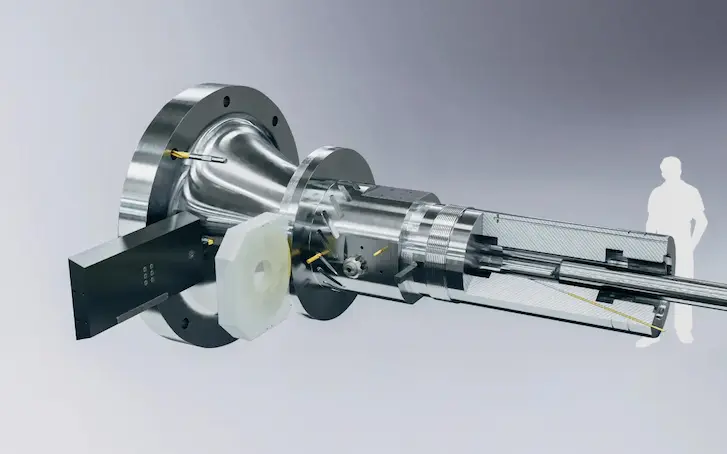

Complete machining of rotating parts

- Wbc ≤ 200

- Øoc ≤ 4 m

- Lbc 25 m

- Ra ≥ 0,8 μm

- O 0,005

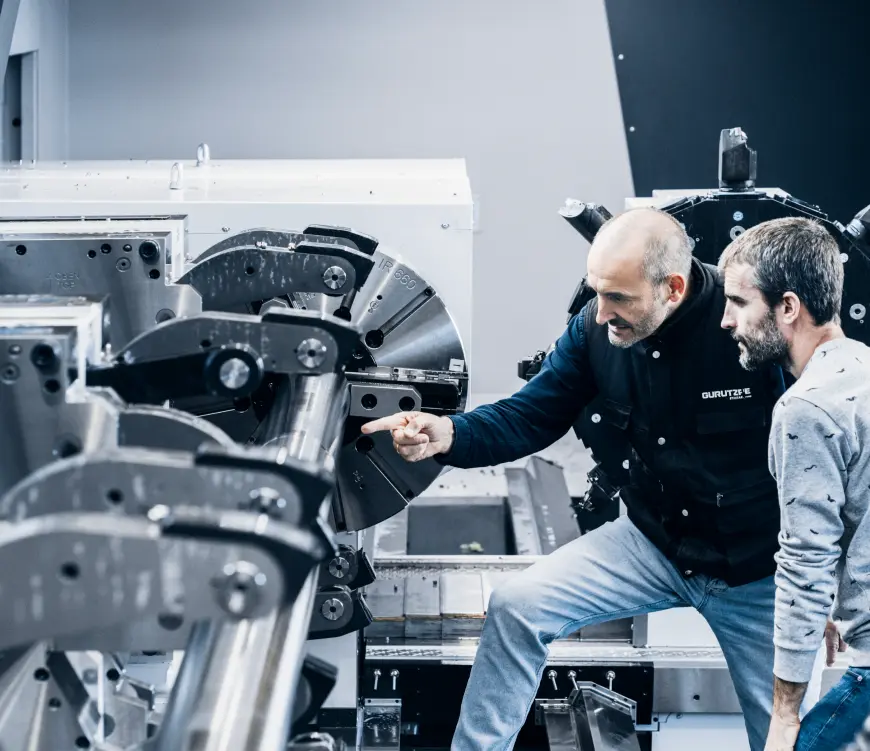

GURUTZPE designs and manufactures multitask CNC horizontal lathes in close collaboration with its customers.

| number of operators | number of machines | number of programs | number of tools | tools | chips & waste management | |

|---|---|---|---|---|---|---|

| Conventional Solution |

|

|

|

|

|

|

| GURUTZPE Solution |

|

|

|

|

|

|

The process of turning your needs into Turning Solutions. We are focused on the quality and cost of your workpiece probing.

GURUTZPE optimises machining processes, extends the working life of your machine, and reduces operating costs.