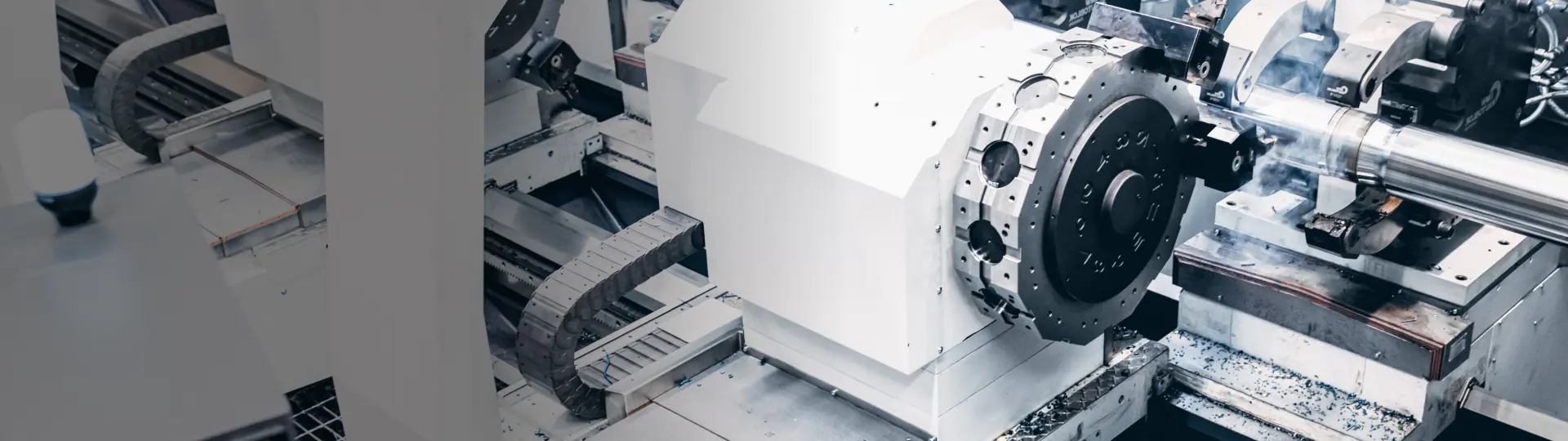

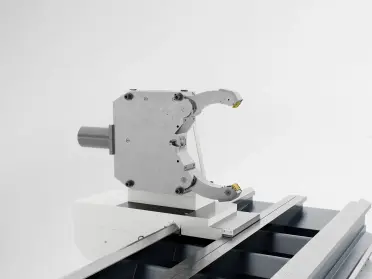

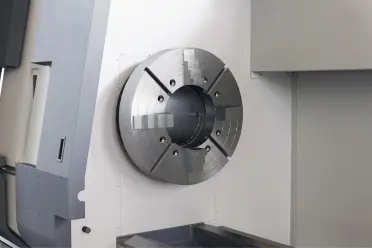

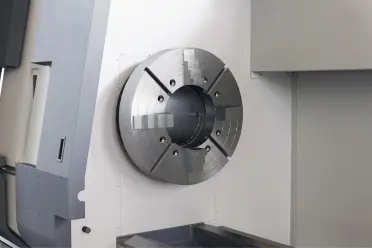

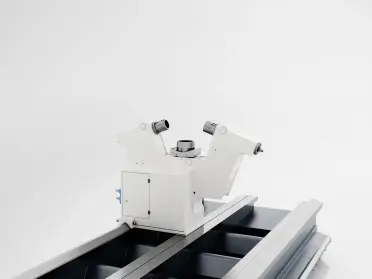

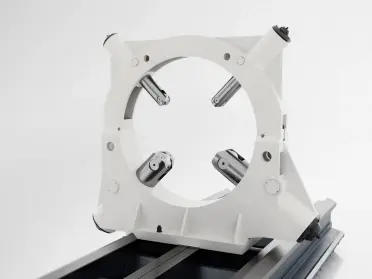

OD External turning

Main turning module for our machines, directly secured onto the machining carriage or interchangeable using the FAMOC system.

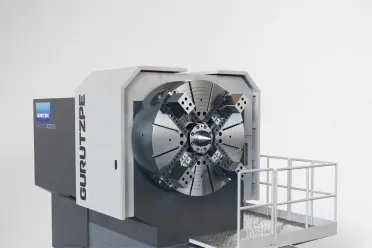

GURUTZPE solutions allow the user to focus the machine’s functions on specific operational needs, guaranteeing an optimal return on investment.

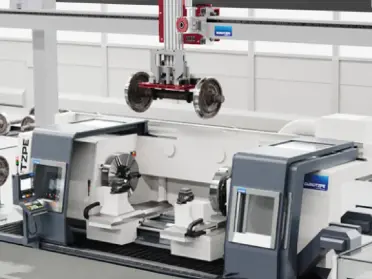

In addition to the regular components that make up the machine, GURUTZPE has a wide range of technologies and accessories that enable and facilitate critical machining operations on the piece.

In this way, we transform the lathe into a multitasking machine, in which a wide variety of operations can be performed without the need to transfer our customers' parts to other machines in their workshop.

Main turning module for our machines, directly secured onto the machining carriage or interchangeable using the FAMOC system.

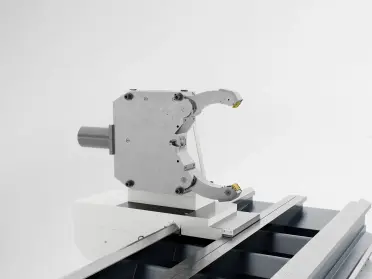

Modules for adaptation of internal boring bars, specially manufactured according to the design criteria of the main manufacturers of this type of tool, to give the highest necessary rigidity for their correct operation.

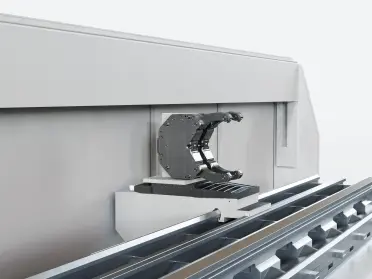

Modules designed for high-precision milling operations, mounted on our machines’ milling column. These modules allow a wide range of processes, including flat surface milling, slotting, and complex shaping.

We collaborate closely with leading milling tool manufacturers to ensure seamless integration, providing maximum efficiency and precision in every milling operation.

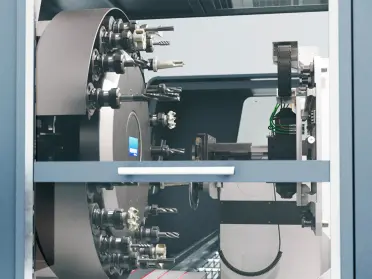

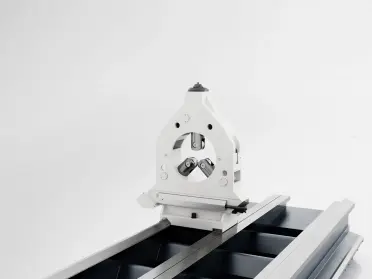

Modules for the adaptation of boring, contouring and facing heads, mounted on the milling column, both manual and automatic control (“U” axis).

We work hand in hand with the world’s leading manufacturers (COGSDILL, D’ANDREA…), analysing each particular operation (internal radial boring, flange gasket seats), adapting the machine to the customer’s needs and guaranteeing robust and precise operation.

Advanced systems for drilling operations, designed to accommodate boring bars of various sizes and specifications. These modules provide exceptional stability and precise control, essential for high-precision internal drilling operations.

The systems are easily adjustable to suit a variety of drilling tasks, from small and precise holes to larger diameter bores.

Specialized modules for creating internal and external threads. Equipped with high-precision tools, these systems form accurate and uniform threads on a variety of materials.

Advanced motion control technology ensures accuracy in thread pitch and depth, resulting in high-quality threads with excellent surface finish.

Modules for adaptation of grinding heads, on the actual turret or interchangeable using the FAMOC system, specially designed to obtain good surface finishes in certain areas of the customer’s parts.

Modules for adaptation of burnishing tools, on the turret itself or interchangeable using the FAMOC system, specially designed to obtain good surface finishes (roughness Ra 0.2-0.4) without the need for grinding operations.

Innovative integrated measurement systems in our machines ensure utmost precision in machining operations. These measurement modules use cutting-edge technology for real-time measurement of workpieces, ensuring dimensions and tolerances meet the strictest standards.

In-process measurement allows for instant adjustments, enhancing machining efficiency and ensuring the quality and precision of each manufactured piece.

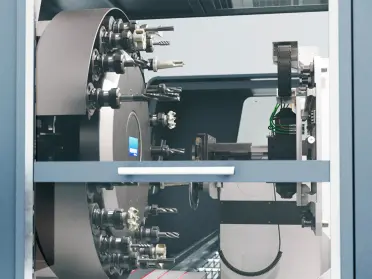

Our versatile 'Combined' module integrates multiple machining operations into a single unit, combining functions like turning, milling, boring, threading, and measurement for efficient and precise machining

GURUTZPE offers a wide range of machining modules, with the aim of covering all the operations that our customers have to perform on their parts, without the need to move them around to other machines. Saving set-up and handling times.

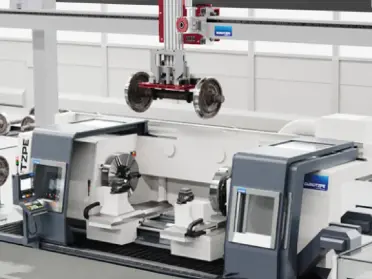

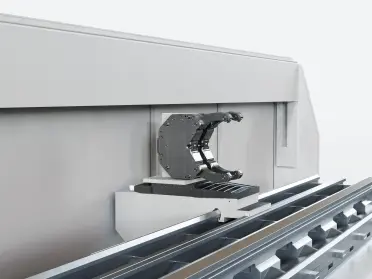

For this we have different ways to change the machining units, always in a simple and fast way, and the most developed of these is the FAMOC System. It is based on a commercial zero-point anchoring system with a positioning repeatability of 5 μ and full interlocking rigidity.

Modular designs optimized in decades of experience and expertise, give the flexibility to compose the desired solutions for your machine.

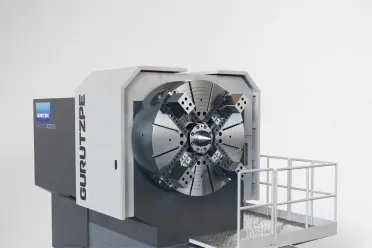

Explore our extensive collection of modular options for machining. With each component refined over decades of expertise, our range offers unparalleled flexibility and precision. From robust chucks to sophisticated enclosures, each element showcases our commitment to quality and innovation. This comprehensive selection allows you to tailor your machine with the precise features and components to meet the rigorous demands of modern machining.

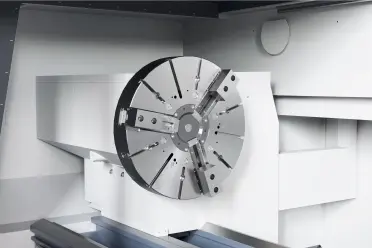

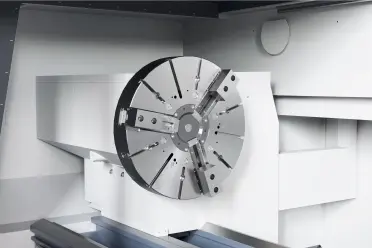

The importance of good clamping of the part is essential for the correct machining of our customers’ parts and to meet their exacting tolerances.

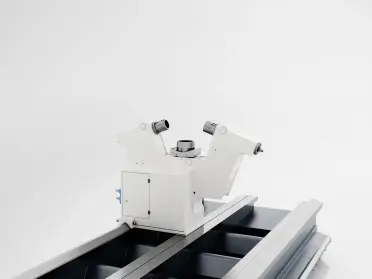

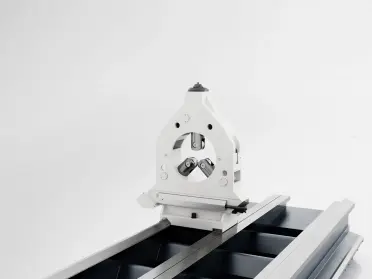

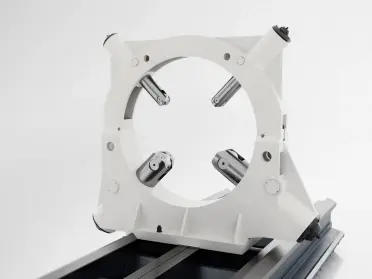

Steady rests are a fundamental element of a lathe to ensure the perfect centring of the part to be machined, support its load and the cutting forces generated.

The protection of the operators and the environment around the machine from chips and cutting fluid projected during the machining, and reducing noise emissions and the mists generated, are increasingly more demanded requirements in modern installations.

Explore a selection of specialized modules, each tailored to enhance various aspects of your machining operations.

This category includes innovative solutions designed for specific needs, ensuring your equipment is fitted with the latest technology for superior performance and efficiency.

These components are crucial in elevating machine functionality, ensuring operational safety, and boosting productivity in sophisticated machining scenarios.