Description

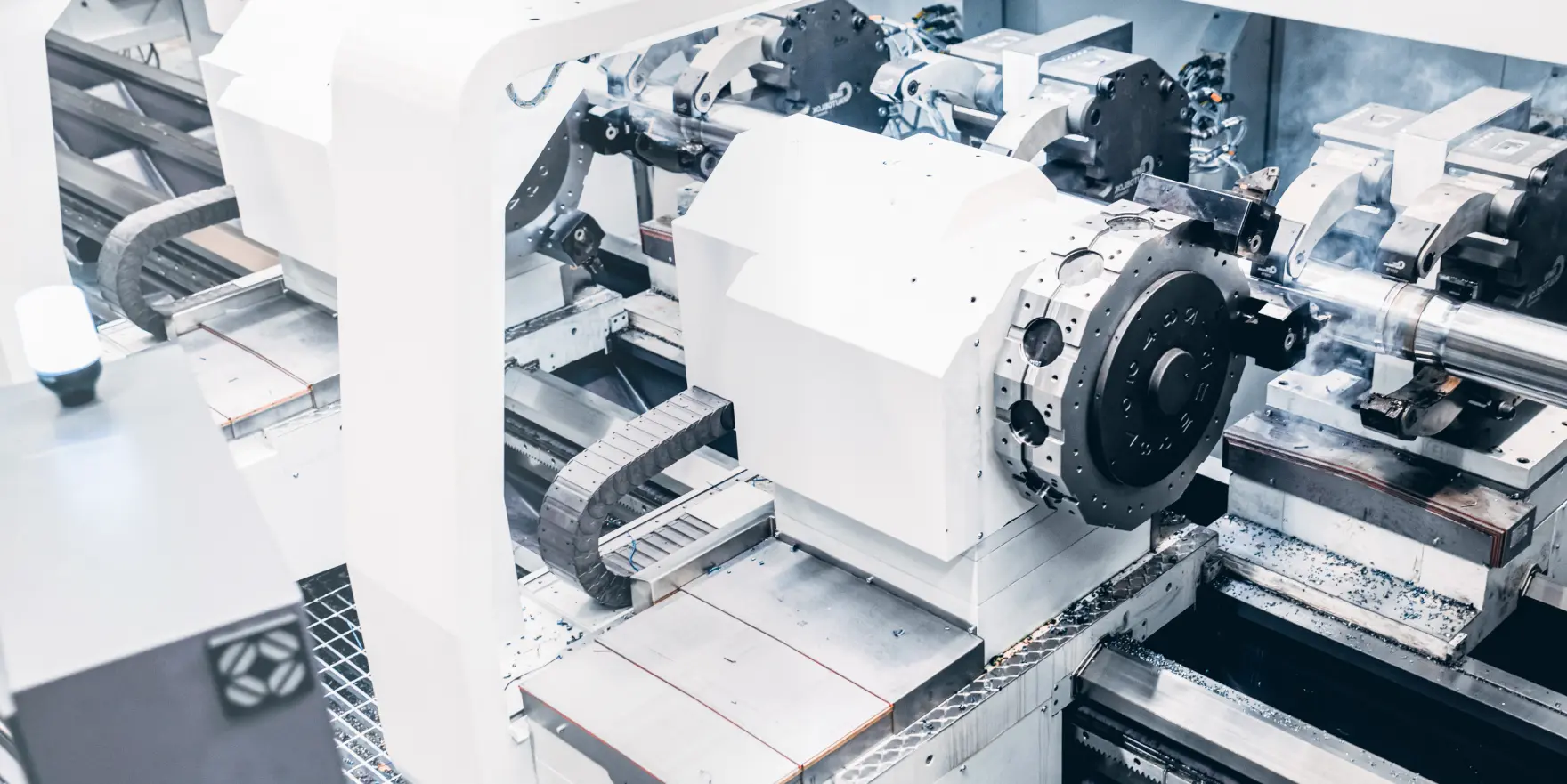

It consists of a hydrostatic guiding system, longitudinally and transversally, using “pump per pocket” hydrostatic technology which guarantees unbeatable performance for rigidity, damping, positioning, and durability.

- Øob ≤ 3.000 mm

- Wbc ≤ 90 t