Description

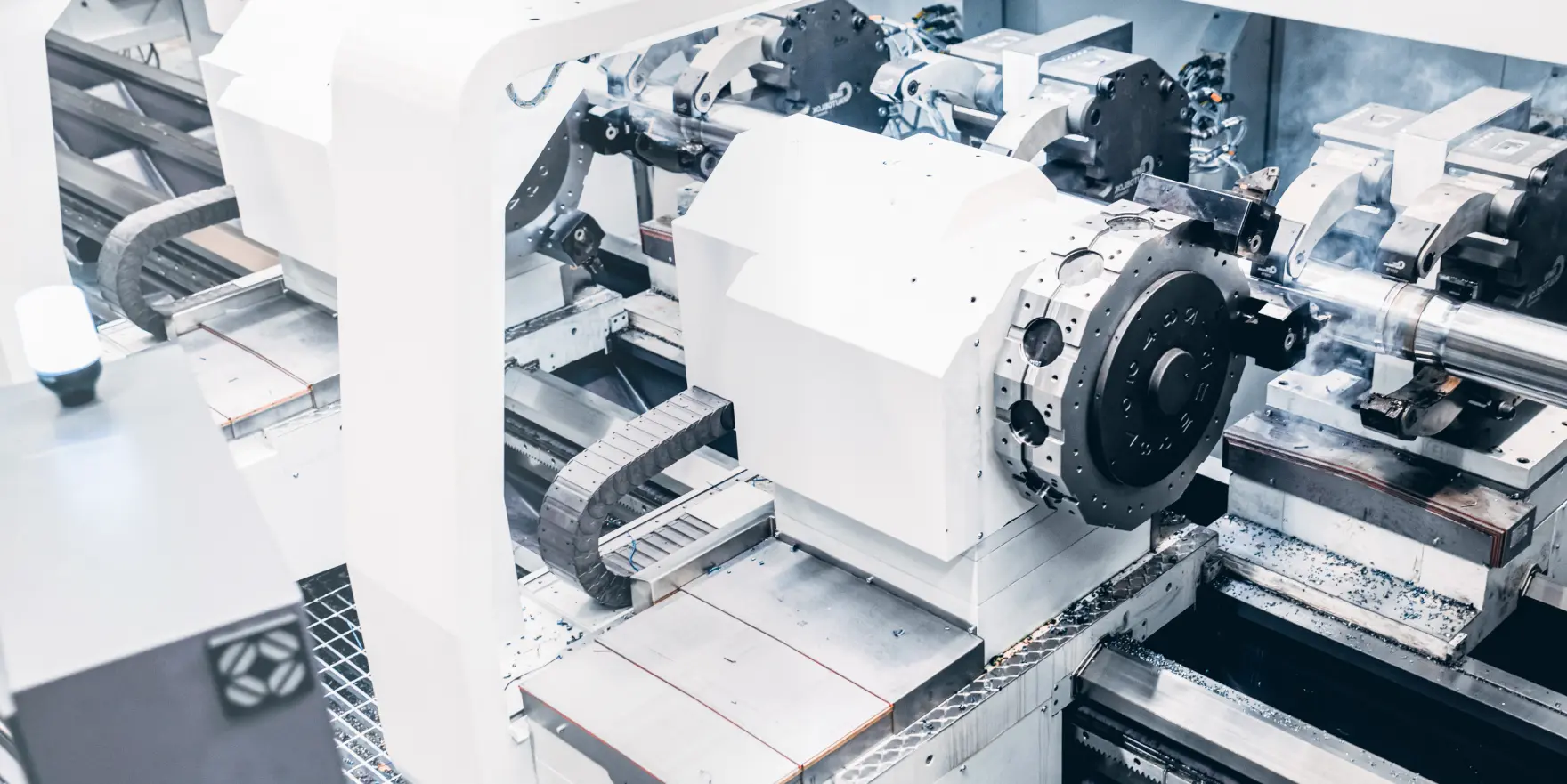

They combine flexibility (carriage crossing) with maximum rigidity, precision, durability, and excellent ergonomics.

The worker can therefore always supervise the machining process comfortably and safely.

These characteristics make the GLH lathe an excellent choice for different machining operations, allowing a wide range of large pieces to be produced.

- Øob ≤ 3.000 mm

- Wbc ≤ 90 t