> Products > Accesories > Machining modules

GURUTZPE offers a wide range of machining modules, with the aim of covering all the operations that our customers have to perform on their parts, without the need to move them to other machines and saving set-up and handling times.

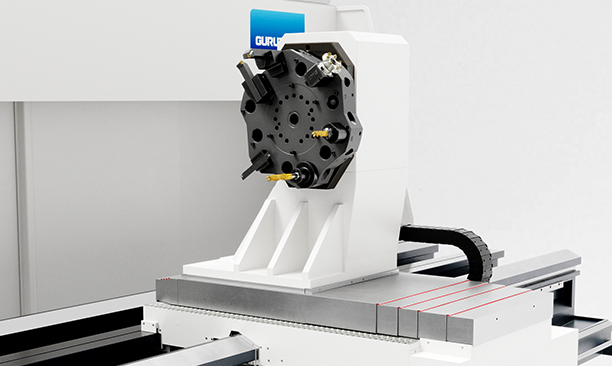

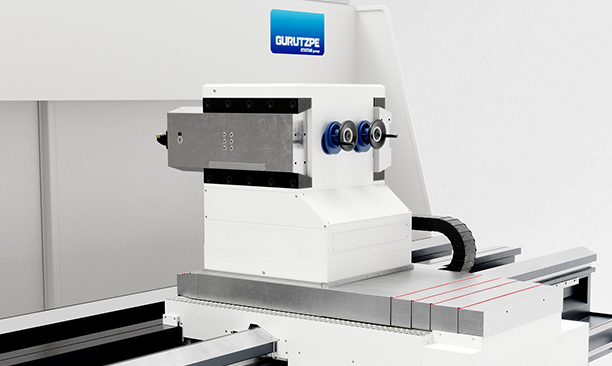

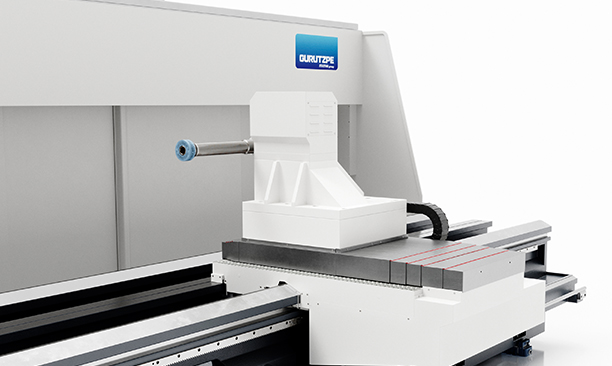

For this we have different ways to change the machining units, always in a simple and fast way, and the most developed of these is the FAMOC System.

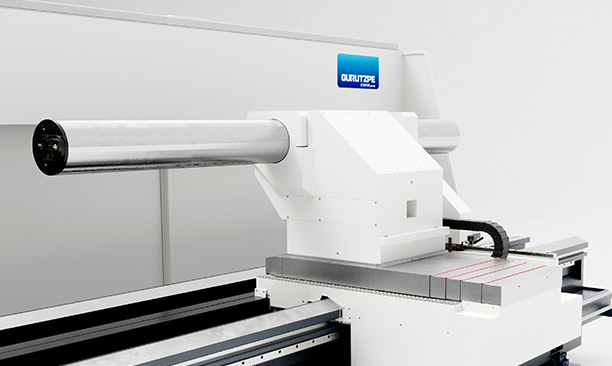

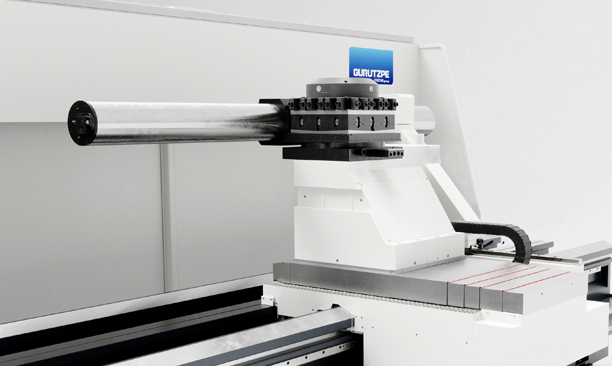

The FAMOC system (FAst Machining Operation Change) is based on a system of commercial zero-point anchors, with a positioning repeatability of 5 μ and full interlock rigidity.

In addition to the contact surface of the anchoring elements, the GURUTZPE design guarantees an additional perimeter contact surface and an additional bolted interlock for extreme operations. On this unique mechanical design, the appropriate fluid and electric fast connections are integrated within its fairing. All this guarantees a robust securing system, with superior precision and fast operation, giving the machine the possibility of changing from a turning function to a milling function in less than 5′, for example.

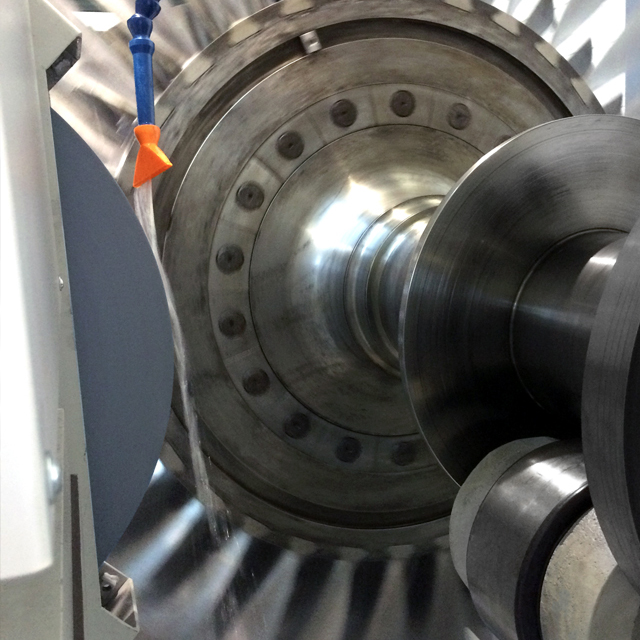

Main turning module for our machines, directly secured onto the machining carriage or interchangeable using the FAMOC system, with the following different configuration possibilities:

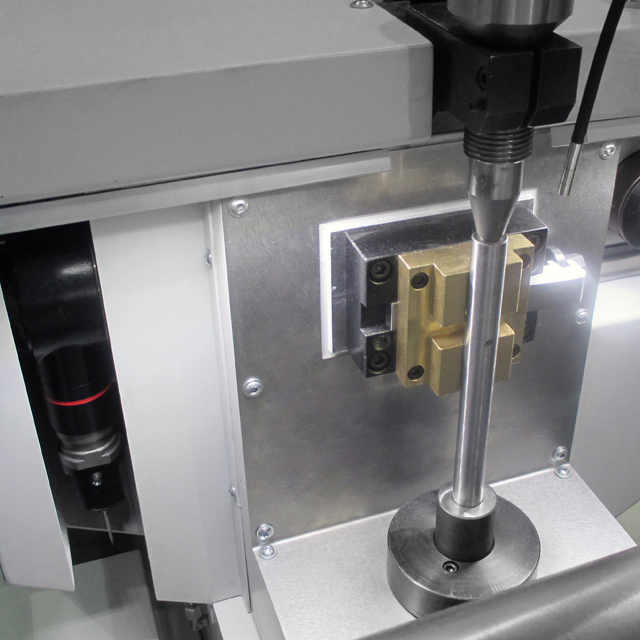

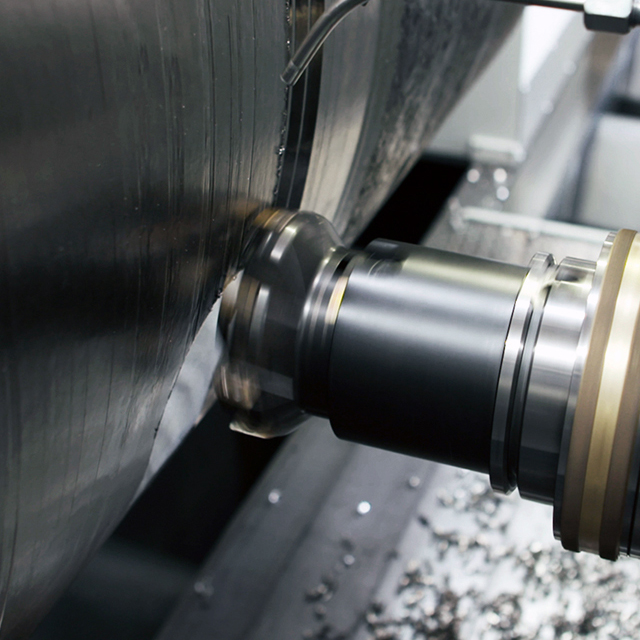

Modules for adaptation of internal boring bars, specially manufactured according to the design criteria of the main manufacturers of this type of tool, to give the highest necessary rigidity for their correct operation:

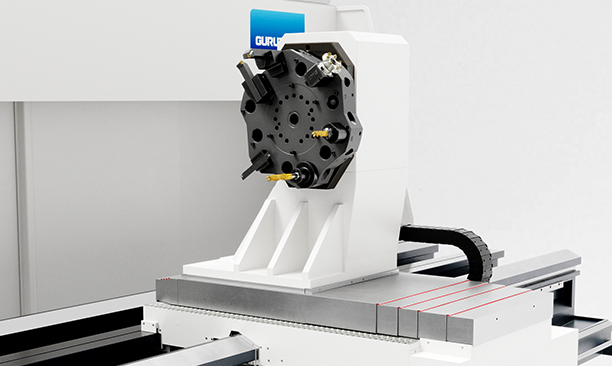

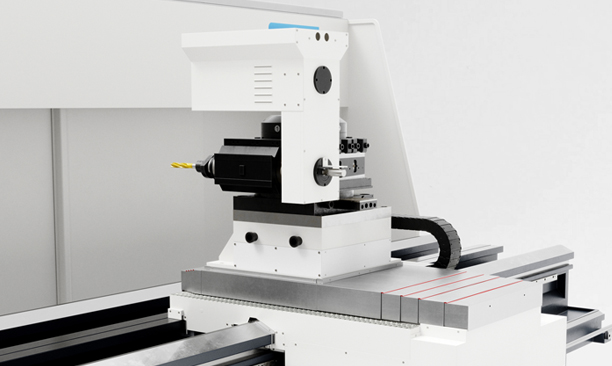

Units designed for milling, drilling, threading, etc. There are a wide variety of types of units and their adaptations on the lathe:

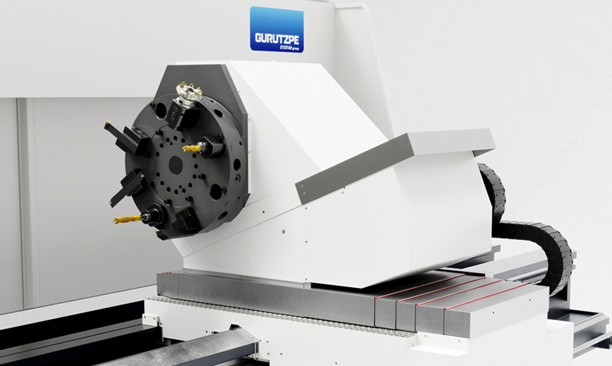

Motorized disc turrets, 8 or 12 positions, directly secured on the machining carriage or interchangeable using the FAMOC system:

Auxiliary milling modules in square turret:

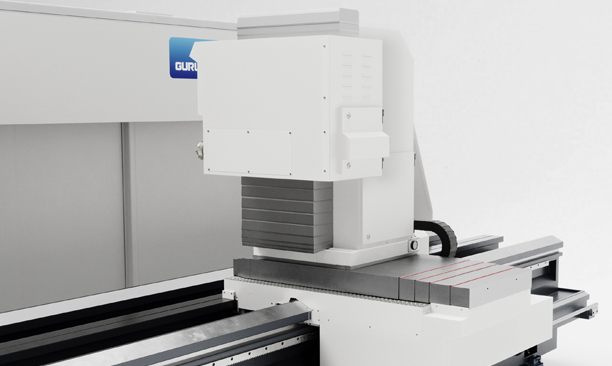

Milling columns, directly secured to the machining carriage or interchangeable using the FAMOC system:

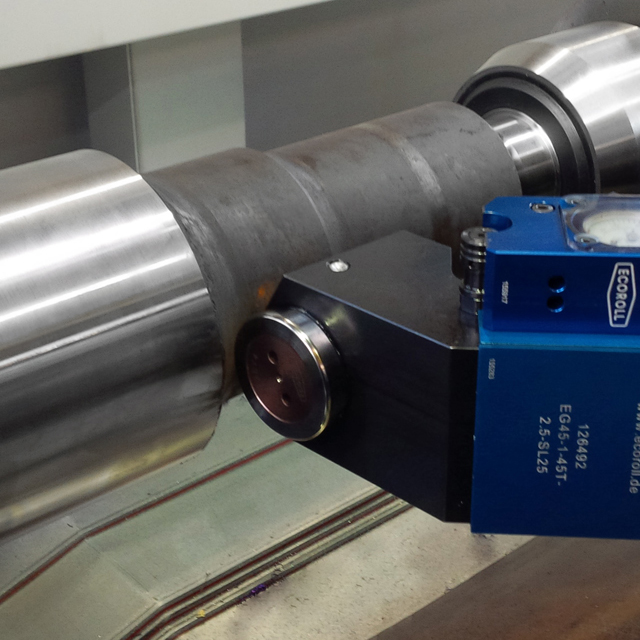

Modules for adaptation of burnishing tools, on the turret itself or interchangeable using the FAMOC system, specially designed to obtain good surface finishes (roughness Ra 0.2-0.4) without the need for grinding operations:

Modules for adaptation of grinding heads, on the actual turret or interchangeable using the FAMOC system, specially designed to obtain good surface finishes in certain areas of the customer’s parts:

Modules for the adaptation of boring, contouring and facing heads, mounted on the milling column, both manual and automatic control (“U” axis).

We work hand in hand with the world’s leading manufacturers (COGSDILL, D’ANDREA…), analysing each particular operation (internal radial boring, flange gasket seats), adapting the machine to the customer’s needs and guaranteeing robust and precise operation.

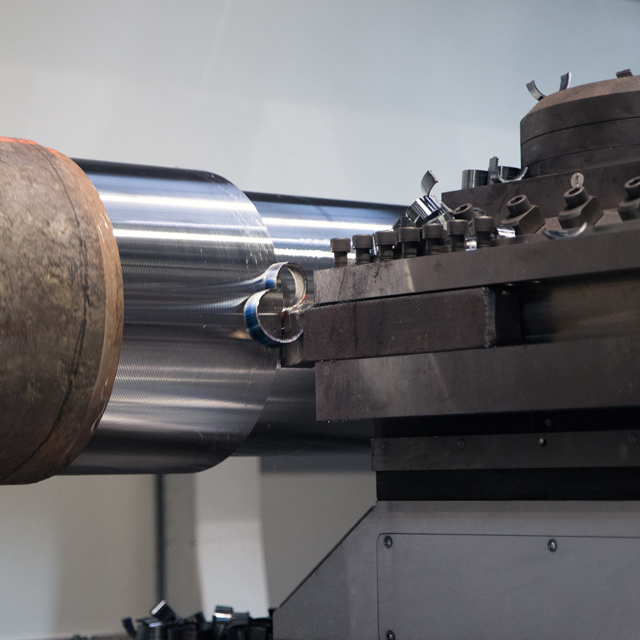

Module to adapt it on the machining carriage or interchangeable using the FAMOC system, specially designed for the machining of ribs and marking on lamination rollers used for the manufacture of rebars: