Description

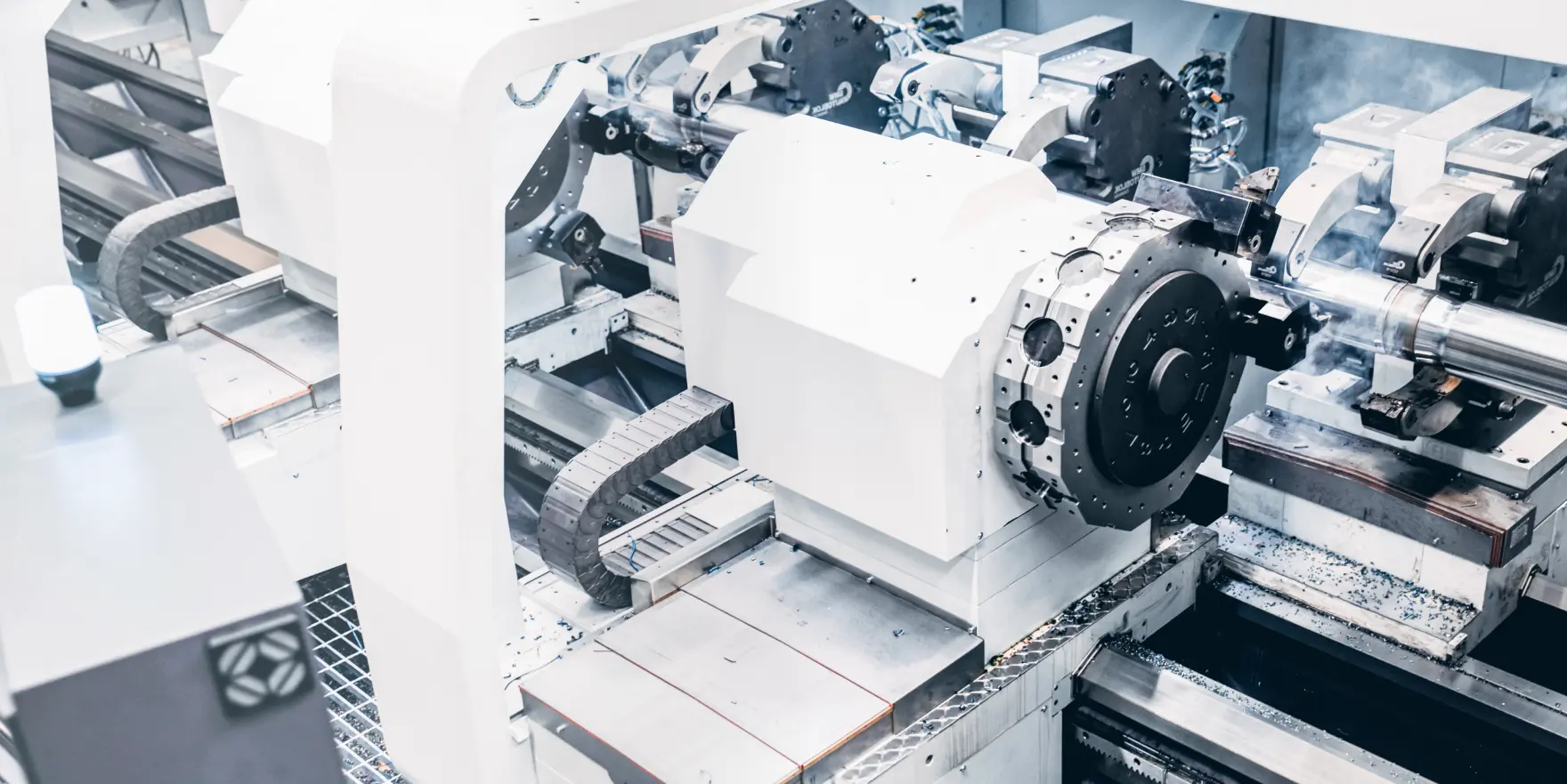

The machining carriage consists of a hydrostatic guiding system, longitudinally and transversally, using “pump per pocket” hydrostatic technology which guarantees unbeatable performance for rigidity, damping, positioning, and durability.

The best guiding system for heavy precision machines.

- Øob ≤ 4.000 mm

- Wbc ≤ 200 t